Electrogalvanised Steels

Our electrogalvanised steel is coated by elctrodeposition on both sides with a pure Zinc Layer which gives it protection against rusting

Certification - Zintec

Certified to European Standard EN 10152 - Quality Standard DC 01

Stainless Steel

We use 304 Grade Stainless Steel with a Brushed Finish for aesthetics

Certification - Stainless

Certified to European Standards BS 304S11 / BS 304S31 / EN 1.4301 / EN 1.4307

Powdercoating Finish

Our Powdercoat Finish is especially designed where high corrosion resistance, optimum mechanical properties & excellent gloss retention are required.

Powder Properties

A thermosetting powder coating based on a corboxylated polyester resin and a multifunctional curing agent

Testing Methods & Certification

All test carried out on material pretreated to the specifications described in BS 6496 : 1984, the following is a portion of testing which is carried on our Powdercoating materials range

Hardness (ISO 2815) Buchholz Indentation test

Flexibility bend test (ISO 1519) (BS 3900: Part E1: 1970

Adhesion (ISO 2409) Cross hatch (BS 3900: Part E6:1974 Classification Gt 0

Impact Test - Falling Weight (ECCA T5) (BS 3900: Part E7: 1974)

Acetic Acid Salt Spray (ISO 9227) 1000 Hours +

Humidity (DIN 50017, BS 3900: Part F2: 1973) 1000 Hours +

Natural Weather Resistance (ISO 2810)

Accelerated Weathering (ISO 11341, DIN 53231)

Fire Resistance Details

Fire Reistant to BS 476 : Part 6 : 1989 Fire Propagation & BS 476 : Part 7 : 1987 Spread of Flame Class 1

What is SteriTouch?

SteriTouch® is a range of additives which prevent harmful bacteria and mould growth on surfaces. Based on the natural sterilising properties of silver, SteriTouch® protection is especially important in healthcare environments where hygiene is critical, preventing the growth of infection causing bacteria such as MRSA and E.Coli.

Where is it used?

SteriTouch® is used as standard on all of our Healthcare Range of Products

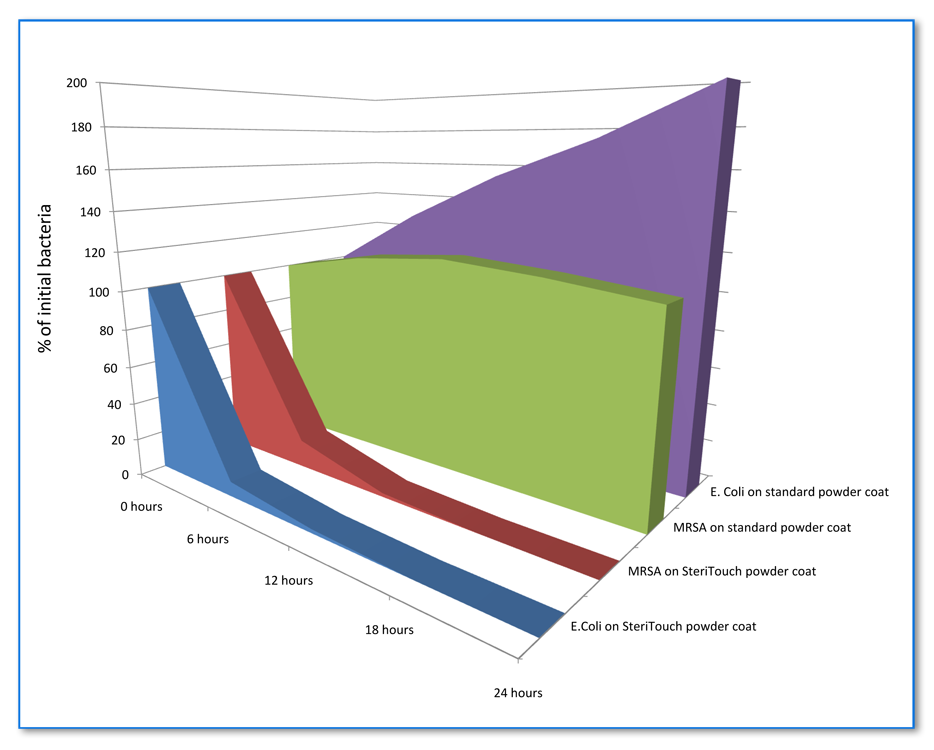

Independent laboratory testing

Confidence in the accuracy of results is important in any testing regime, but is even more so when evaluating antimicrobial performance. SteriTouch® uses only established laboratories specialising in antimicrobial testing, ensuring consistent and repeatable results.

The standard organisms used in the JIS/ISO method are MRSA and E.Coli, however SteriTouch® has been tested against a range of other organisms

The test method - JIS Z 2801 & ISO 22196

The standard test for evaluating the performance of antimicrobial surfaces is the JIS Z 2801:2000 or ISO 22196 method, which can be summarised as follows...

Each test sample is inoculated with a suspension of the test organism (for example, MRSA). The inoculum is held in contact with the test sample using a sterile polyethylene film. All test samples are inoculated in triplicate, with an additional three replicates of the control. The bacterial population on three control replicates is evaluated immediately following inoculation. This is assumed to be the initial population on all test samples (i.e. the population at zero hours). The remaining samples are incubated for the test period (typically 24 hours) at 35°C, at which time the bacterial population is evaluated.