Date: April 13

Client Name: Tallaght Hospital Recycling Project

Date of Installation: December 2011

Project Summary

Supply and fit of 100 Mobile Single Open Type Recycle Bins. Designed in conjunction with the Hospitals requirements for their new recycling plan.

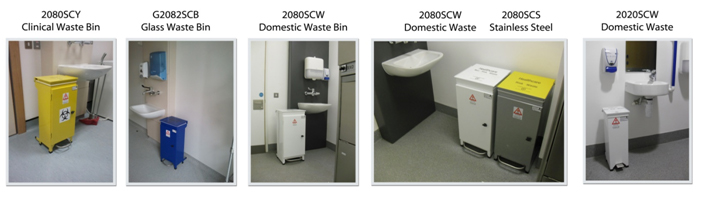

Products Supplied

Single Mobile Recycle Bin

- Open type frame design where bag is visible

- Code: 3200

- 4 X Swivel Castors fitted (2 X lockable)

- Silent closing lid

- Special medical grade shock cord fitted for retaining bag

- Lid powdercoated recycle green

Colour Coding & Labelling

White body with green lid, waste Information printed directly on lid through a screening process

“We had a HIQA audit recently and the bins were given the thumbs up…… I was delighted with both the bins supplied and the level of service Taltech offered. On top of that the price was right. I would definitely recommend them.”

Background

The hospital was involved in a project which merged three different facilities into one. Old bins were brought over from the three hospitals however it quickly emerged that there was a shortfall and some of the existing bins were no longer suitable. The new facilities required the implementation of a fresh recycling programme and Anthony O’Toole was responsible for purchasing appropriate waste bins. “Taltech was an existing supplier working with the Materials Management team here so we spoke to them about our requirements. Firstly Brian at Taltech was able to identify the different bins we had already and advise us how old they were. Then we needed to design a new bin to meet our specific recycling needs and we found it very easy to deal with Taltech , partly because of their own industry expertise but also because they know the hospital here so well and understood what we needed.”

However pricing was also an important factor in deciding to work with Taltech “We were looking for the best value and we worked with them on the price. When we had a large order it became highly cost effective”.

The Bin Design Process

Taltech often works with companies to develop bespoke bins and this project had specific requirements. “We needed slow closing bins – you don’t want lids slamming in an ICU for example, but we also wanted to minimise the “moving parts” as this makes for a bin that’s easier to clean and requires less maintenance.” Taltech liaised with the hospital to recommend the best design and ultimately this went into production.

Planning of Bin Locations

Like most facilities, Anthony says the hospital suffers from “nearest bin” syndrome. “People will always put rubbish into the nearest bin so we needed to identify “hotspots” so that the right bin was the nearest to the point of waste disposal – whether that be generic waste or clinical waste – we had to make it as easy as possible for people to dispose of the waste into the right bin. Taltech helped us identify the right locations as this was part of a detailed planning process”.

Labelling, Classification of Waste

In addition to identifying convenient bin locations, Anthony analysed the waste disposal process – starting at the Theatre. “We identified the different types of waste at the point of disposal and we realised that we needed to do three things – first of all we had to identify what could be recycled and what couldn’t be and secondly we needed generic names on each item so that the nurses could easily identify them. Finally we needed to screen print the lids of the bins so there was total clarity on what waste each bin could take. Taltech helped us throughout this process and they screen printed the bin lids with a list of waste it could handle – I was delighted with the way the whole thing was managed”

Strong Product Performance

The performance of the bins has been strong since the installation.